About Us

About us

Imballaggio was the first paper bag factory in Latin America to obtain Food Safety certification. Our commitment to the quality and safety of our products is evidenced by this certification.

At Imballaggio, we also highly value sustainability. Since 2012, the papers we use in our products have been FSC® certified. This certification verifies that the papers used come from man-made forests and are responsibly managed.

Furthermore, we believe that the sustainability of our business is linked to establishing relationships built on ethics with our stakeholders – customers, employees, suppliers, public entities, and associations. Proof of this is that since 2013, we have been members of Sedex Global – a global membership organization dedicated to driving improvements in ethical and responsible business practices in global supply chains.

Our beginning

Founded in 1893, initially under the name of Fábrica de Sacos São José, in Praça da Sé, downtown São Paulo, Imballaggio is a pioneer in the manufacturing of paper bags, responsible for introducing various bag models to the Latin American market.

In 1996, with the separation of plastic and paper units, we transferred our operations to Belo Horizonte, Minas Gerais. Then, in 2010, after a long period of planning, we chose to invest in Lagoa Santa, also in Minas Gerais, in the construction of an industrial plant designed and sized specifically to meet sanitary standards and good manufacturing practices.

Throughout these 130 years, we have always sought to provide our customers with the best possible technical solution. Our technical team – comprised of engineers and professionals in the field – has tirelessly sought to improve our products, equipment, and processes. This commitment to innovation is evidenced by the number of patents applied for and the numerous awards won. It’s no coincidence that our slogan is TRADITION IN INNOVATION.

Our infrastructure

Imballaggio is strategically located in Lagoa Santa, Minas Gerais, metropolitan region of Belo Horizonte, 5 minutes from Belo Horizonte International Airport, in Confins. We are located in a closed industrial condominium (Condomínio Industrial do Papel – CIP), belonging to the Genesco Aparecido de Oliveira Industrial District (DIGAO).

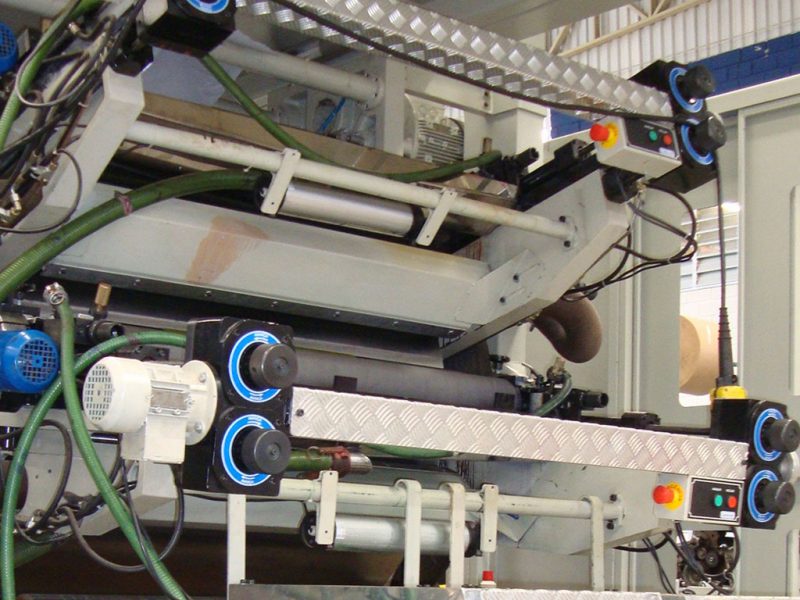

When it comes to paper bags, Imballaggio has one of the largest and most diversified industrial parks in Latin America. There are more than 30 pieces of equipment designed to manufacture different types and models of paper bags, from the simplest to more complex or special bags.

At full capacity, our industrial plant is capable of converting up to 20,000 tons per year, and we currently operate at 65% of our capacity, with most equipment operating in 2 shifts.

Starting in 2018, Imballaggio outlined a consistent investment plan to modernize its equipment. In addition to increasing productivity, we seek greater integration of the factory floor with company management, industry 4.0, and the adaptation of equipment to food and work safety standards.

Imballaggio also has a complete laboratory structure for physical and microbiological tests on our raw materials and products.

Timeline

Founded in Praça da Sé, São Paulo, under the name Fábrica de Sacos São José. It was the first paper artifacts factory in Latin America, producing paper bags manually.

In the early years of the 20th century, the first mechanical devices appeared to assist in the printing and manufacturing of paper artifacts.

With the industrialization of

In post-war Brazil, the first paper bag machines appeared.

Moving the factory to Belo Horizonte, Minas Gerais. Acquisition of new

equipment and expansion of the product portfolio.

Winning the ABFlexo-FTA Award for best flexographic printing with the Café 3 Corações package.

Start of work on new facilities in Lagoa Santa, Minas Gerais. Factory designed to meet the demands of the food and pharmaceutical sectors.

Inauguration of the new headquarters at CIP - Condómínio Industrial do Papel in Lagoa Santa, Minas Gerais.

Certification of products with the FSC® seal. Seal that identifies that the paper used in our packaging comes from a sustainable management area.

Certification in Quality Management in ISO 9001:2008

Certification in Good Business Management Practices. It has 4 evaluation pillars:

worker health and safety; labor standards; environment; business ethics.

ABRE Award 2014 with the Valvebag-Strip bag. Bag for cleanroom environments. Patent applied for.

Beginning of the company's internationalization process. First exports made to South American countries.

ABRE 2016 award with the Hexabag bag. Bag with maximum protection and barrier to gases, odors and humidity.

International recognition of the Hexabag bag with the WPO - World Packaging Organization award.

Certification in Quality Management in ISO 9001:2015

Expansion of the plant with the creation of production areas with the

clean room concept.

Start of the Imballaggio 4.0 project. Automation of processes with the acquisition of new equipment.

Certification to the BRCGS Packaging Issue 6 standard, Product safety to meet the growing demands of industries

food and pharmaceutical.

Re-certification in the BRCGS Packaging Issue 6 standard,

Product safety, obtaining an AA grade.

2nd International Prize with Hexabag+. New version of the bag with a high barrier to gases, odors and humidity.

Premiações

Prêmio ABRE (2014)

Com a embalagem Valvebag Strip

Prêmio ABRE (2016)

Com a embalagem Hexabag

Prêmio WPO (2017)

Com a embalagem Hexabag

Mais Premiações

- 2003 - Conquista do Prêmio ABFlexo-FTA

- 2011 - Certificação FSC - Forest Stewardship Council

- 2012 - Certificação ISO 9001:2008

- 2013 - Certificação Sedex Global.

- 2018 - Certificação ISO 9001:2015

- 2021 - Certificação BRCGS